Combines New Holland Series CR: significant improvements

More than 35 years ago, New Holland has completely changed the way to harvest, providing innovative technology for Twin Rotor ™ combines. The latest generation of CR combines series continues a series of rotary combines and offers farmers all over the world the best in class quality of grain and straw, through careful multipass action. The use of such innovative systems as SmartTrax ™, IntelliCruise, IntelliSteer ™, Opti-Spread ™ has additionally improve performance and maintain its leading position as the CR series combines some of the most advanced and efficient in the world.

Outstanding performance

In 2008, the series combines CR entered the Guinness World Records as the highest performing processor. Less than eight hours managed to remove 551 tonne of grain. This was achieved thanks to a powerful 571-horsepower engine Cursor 13 of FPT Industrial cleaning and improved technologies, including a system of automatic guidance IntelliSteer ™, allowing non-stop harvest of twenty-four hours a day. Combines CR series are willing to work for as long as you need.

Excellent quality cleaning

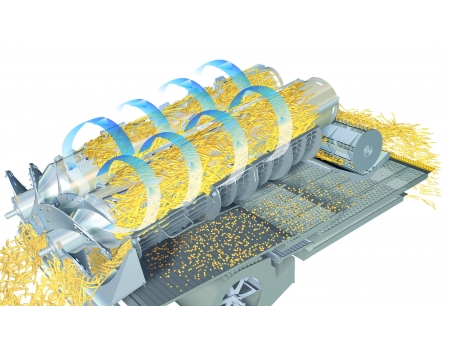

Technology is gentle, but highly effective cleaning Twin Rotor ™ ensures superior quality of grain and straw. System Opti-Clean ™ allowed to get rid of damaged grain and achieve industry-leading 0.1% for the cleanest grain sample. There are two types of rotor to meet the different requirements for cleaning.

An absolute pleasure to drive

In a comfortable cabin combiner you feel immediately at home. The largest (3.12 m3) and the quietest (74 dB (A)) of the cab on the market is color touch screen monitor IntelliView ™ IV for intuitive control of all key parameters cleaning with the fingertips. This helps reduce fatigue and improve performance during prolonged work.

The history of modern cleaning company New Holland combine harvesters

Produced in Zedelgeme

Combines advanced CR series made in Zedelgem, Belgium, where the International Centre for improving the technology of harvesting of New Holland. It was here over 100 years ago Kleys Leon (Leon Claeys) built his first threshing machine that changed the idea of cleaning up. The city's name became synonymous with Zedelgem innovations in clean technology, when in 1952 there was established the first European self-propelled combine harvester. Today engineers are dedicated to developing technologies grain, are working on a new generation of cleaning equipment. Combines a series of CR and all advanced products for cleaning - standard combines CX, large hay press BB, forage harvester FR - continue to lead the industry through elaborate process of product development and extensive knowledge of the personnel of industrial enterprises world-class.

1975: The company introduces the New Holland TR70 (145 - 168 hp), which was the first to combine the technology Twin Rotor ™. It's forever changed the idea of harvesting.

1979: The second generation of the technology Twin Rotor was presented on the combines TR75, TR85, TR95, whose thickness was increased to 155-225 hp

1984: The third generation of the machine features a larger cab, improved visibility and rotors S3. Farmers have met with the approval of the model TR76, TR86, TR96. 1993: Almost ten years later, TR87 and TR97 Combines fourth generation excelled increased power.

1997: simplified management for TR88 and TR98 combines fifth generation allowed to tame their increased power and efficiency and cleaning performance.

1999: The main differences TR89 and TR99 models from previous generations has been to increase the capacity of the grain tank and improved visibility.

2002: in the margins of the world appeared combines the seventh generation of attractive sleek. CR960 and CR980 models with completely redesigned, longer rotors, larger cabin and the first grain cleaning with automatic leveling rotary processor have become extremely popular. By the way, they developed the power to 428 hp

2004: The beginning of the new century saw the launch of the Twin Rotor Combine in Zedelgem, Belgium, which is the center of technology to improve the harvest of New Holland.

2005: thirty years of success Twin Rotor ™ technology has been noting the monitor IntelliView ™ II for the precise control of the machine.

2007: Series CR Elevation became the eighth generation of harvesters and received a number of productivity-enhancing features, including Tier 3 engines up to 530 hp, the system Opti-Clean ™ and IntelliCruise ™ system to ensure a constant flow of traffic and Variable fan speed to optimize performance and increase the comfort of the operator.

2008: CR9090 combine was officially recognized as the most productive in the world. He broke the previous world record harvest, is listed in Guinness World Records. Less than eight hours he was able to remove 551 ton wheat.

2010: Series CR said 35-year anniversary. In Brazil, the manufacture of model CR9060 for Latin America.

2011: started the production of Twin Rotor Combine ninth generation with engines ECOBlue ™ SCR Tier 4A, improved performance and best in class quality of grain and straw.

EXCELLENCE IN EVERYTHING FROM THE FRONT

Specialists of New Holland knows that the cleaning process starts with culture. The way she gets in the car, determines the quality of cleaning. Therefore, for the different types of cultures and environments created a wide range of our own headers that meets all requirements. Width headers varies from 6 to 10.7 meters. You can choose the configuration that satisfies all the requirements for cleaning requirements.

HIGH AND HPC reaper for combine harvesters

Traditional high-performance and сверхвысокопроизводительные header for combine harvesters are suitable for use in standard conditions. Сверхвысокопроизводительная harvester fitted with a mechanical reel drive for economical harvesting and develops an impressive speed of 1,150 cuts per minute for superior performance. High-performance cutterbar different design for heavy duty hydraulic reel, which is perfect for cleaning the heaviest crops. Increased to 606 mm screw diameter and speed of 1150 cuts per minute increase productivity, speed and volume of the feed material.

FULLY INTEGRATED KNIVES FOR RAPE

Additional 18-fluted blades for rape pass through tangled stems like a scythe. They can be easily and quickly installed reaper Varifeed ™. They ensure a more effective cleaning of rape and controlled color touch screen IntelliView ™ IV. If the blades are not required, they can be kept in a special section at the very header.

Reaper VaRifeed ™ for combine harvesters: SETTING FOR ALL TYPES OF CULTURES

Maize Varifeed ™ is perfect if you want to ensure optimum cleaning and constant cutting height in the fields with the culture of different heights. Longitudinal position of blades for ideal flow can be adjusted between 575 mm. Screw diameter of 660 mm with deep coils for fast and uniform supply of even the heaviest crops. Retractable fingers across the entire width between the turns of the screw moves the material down a grain auger. To ensure a continuous supply of the fingers can be adjusted in all directions from the cockpit with electro-hydraulic system. The width of such headers varies from 7.32 to 10.67 meters.

FLEXIBILITY FOR GUARANTEED effective cleaning

In the hilly area, use header SuperFlex. Flexible support blade can be bent by 110 mm on uneven surfaces, providing a low cut and a constant height of stubble. Fully floating with deep auger turns for quick and uniform supply of even the heaviest crops. The combination of high (1,150 cuts per minute) speed and hydraulic reel longitudinal adjustment of the cab ensures accurate submission and processing of the material. You can even maintain a given speed ratio reel and running speed to changing speed created a constant stream downloaded.

AUTOMATIC REGULATION header height

Improved automatic header height control can work in three modes.

• In the pre-compensation using ground contact pressure, which is supported by a hydraulic system for efficient cleaning flattened or low-growing crops, such as peas and beans.

• Cruise Control maintains the set stubble height of stubble height using sensors placed in the bottom of the header, and hydraulic cylinders control header.

• In AutoFloat ™ uses a combination of sensors, providing repeating header uneven terrain. The system automatically adjusts the header to maintain a constant height of stubble and prevent penetration header into the ground.

PERFECT COMBINATION

Corn header with high characteristic tics beautifully with proizvoditelnos Tew CR Series combines

Specialists of New Holland have created a wide range of corn harvesters, which combines perfectly with the series CR. The variants with eight or 12 rows. Headers are designed for safe and effective operation in all crop conditions.

Harvester and reaper. Made for each other.

Folding cutterbar for seamless transportation

Offers traditional curtain corn header and folding cutterbar for frequent transportation. Automatic folding by pressing a button in the cockpit.

Best in class CRUSHING Stems

For fine grinding and qualitative distribution of mulch material can be installed integrated shredders stems. They are perfect with no or minimal amount of operations to prepare the soil. Cutting blade located under the header, and maximum flexibility is guaranteed through independent management of each side. Clients see eye to eye: New Holland offers a truly best-in-class solution.

The reliability of a

Regardless of the size of all the corn harvesters New Holland delivers the highest performance in all conditions, harvesting crops. Rollers steblereza have four knives for intensive lowering stems of any size. Plate of the cab platform regulated electronically and allow you to change the configuration when resizing stalks and cobs. The optional rotary separators further improve the already steady feed stream were killed while harvesting corn.

Improved protection for increased efficiency

Supply system combines a series of CR was significantly upgraded to improve the already high performance. Feeder Model CR9080 now has four chains with connecting rods. This has improved the flow of the grain of the material and make it more uniform feeding into the rotors Twin Rotor. Combines CR series have a high load capacity mounting header, providing unsurpassed performance with even the largest headers. The system improved the stone-guard provides full protection threshing machine.

ADVANCED SYSTEM PROTECTION OF STONES

Detection sensor that is part of a unique system of enhanced protection from stones (ASP), mounted under a closed bottom drum solomopodemnika. In the case of stone swinging door across the width is automatically opened by pushing a stone. This system requires minimal operator intervention and moves the net flow of grain material from the feeder to the rotor. This improves the quality of grain and straw, and productivity, not to mention the automatic protection of internal components supply system, which prolongs battery life.

Deliverance from clogging

Hydraulics reverse instantly eliminates clogging header. Entire header and elevator can be dramatically shifted back and forth in order to effectively eliminate clogging machines to reduce downtime.

Intellicruise ™ SYSTEM FOR PІDVISCHENNYA PRODUKTIVNOSTІ

System avtomatichnoї podachі materіalu IntelliCruise ™ is automatic regulyuє shvidkіst ruhu perednіm way in zalezhnostі Vid zavantazhennya materіalu grain. Sensor in silovіy peredachі solomopod'emnіka postіyno vіdstezhuє zavantazhennya header. In areas іz znizhenoyu vrozhaynіstyu shvidkіst ruhu perednіm zbіlshuєtsya course is automatic, robot dwellers garantuvati combine on povnіy potuzhnostі Square Vid vrozhaynostі.

GRAIN QUALITY CLASS

Twin Rotor ™ technology was developed by New Holland 35 years ago. For nearly four decades, the technology improved and developed, providing users with increasing productivity and quality of grain and straw. Company New Holland knows that the working conditions at different farms may differ, so to meet the requirements of customers were developed rotors of two types and sizes. CR8070-CR8080 models are equipped with standard 17-inch rotors. The model is equipped with a high-CR9080 22-inch rotors for heavy duty work. These machines are of high quality and performance.

Straw

• After passing through a straw beater rotor diameter of 400 mm to the conveyor moves the straw involuntary discharge. This conveyor feeds the flow of straw in the back of the combine.

All in good time

• The rotor blades can be precisely adjusted to speed up or slow down the flow of the grain of the material to change the time of threshing and separation of grains.

GNUCHKІST SETTINGS sektsії pіdbarabannya

Simple vibіr optimalnoї konfіguratsії for pribirannya rіznih cultures Available zavdyaki zamіnnim sektsіyam pіdbarabannya i vіdokremlyuє grata. Proponuєtsya Karpovna nabіr varіantіv - Vid reshіtok s Duzhe thin glass tubes to pіdbarabannya i reshіtok s round bar for zbirannya Kukurudza that soєvih bobіv.

Standard rotor

Іsnuє dvі versії rotorіv S 3: 17-inch W EYAD inlet turns screw i s 22-inch inlet troma turns the screw. The rotor oboh versіy Yea spetsіalna area vіddіlennya that threshing in yakіy zdіysnyuєtsya Karpovna thrashing i vіddіlennya culture. Unіkalna spіralna konstruktsіya rotor Twin Rotor napravlyaє culture back scho pіdvischuє efektivnіst vіddіlennya that thrashing.

S rotor PODVІYNIM Kroken

Available 22-inch varіant rotorіv s podvіynim Kroc. Rotors osnaschenі 44 Elements i vіdrіznyayutsya іntensivnim vіddіlennyam have vazhkih Minds zbirannya. Especially when the stench korisnі visokіy vologostі de mozhlivy rіst produktivnostі to 10%. Dostupnі two rіznih kit, yakі dozvolyayut vibirati konfіguratsії for abo drіbnih pribirannya rice grains and takozh peremikatisya mіzh tsimi konfіguratsіyami.

SELECTION OF BEST CONFIGURATION

For each type of crop harvesters CR provides unsurpassed flexibility. Change whips threshing drum, mixing pins separating wedges rotors Twin Rotor, to ensure optimal threshing and separation for any grain material.

The purest sample of grain

Best-in-class level of grain cleaning and cleanest in the industry sample of grain - it combines a series of achieving CR. This is convincing evidence: a comparative test conducted to evaluate grain samples obtained using different techniques of cleaning, Twin Rotor ™ technology won a landslide victory over competing solutions. The volume of broken grain was only 0.1%. How it was possible to achieve such results? This is made possible thanks to the unique technology Twin Rotor ™, which provides a linear flow of the grain material for gentle handling of grain. Grain quality could further increase by award-winning systems Opti-Clean ™ and Opti-Fan ™.

Technology Orti-fan ™ defies earth's gravity

System Opti-Fan ™ compensates for the effects of gravity on the crops during harvest. Set the desired fan speed on a flat surface, and the system will automatically adjust this speed when moving up or down to maintain the quality of cleaning. When driving up the fan slows down to prevent loss of the sieve. When descending a slope fan rotation speeds up, to prevent the accumulation of dense grain material through the sieve. This effective system requires no operator effort, provides better quality grain samples and reduces losses.

The highest level of cleaning grain, worthy of the highest awards

A large common area with an adjustable air flow (6.54 m2 for model CR9080 and 5.40 m2 for models CR8070 and CR8080) allows high quality grain cleaning process large amounts of grain. System Opti-Clean ™ optimizes the corners and move the stroke treatment system. Pitched Grain Board, prior and upper sieve work independently, optimizing the stage for performance. Extended course sieve and sharp corners move to increase the amount of material in the air to increase the quality of cleaning. Work pitched grain boards and lower sieve of phase with the preliminary sieve and top sieve reduces machine vibration and increases operator comfort.

Streamline

Unique rotary fans create CR Series combines a powerful stream of air with constant pressure and much higher than those competing solutions. Furthermore, the fan is equipped with two holes to supply powerful airflow to the preliminary and upper sieve to improve cleaning.

COMPENSATION side slopes up to 17%

Grain cleaning with automatic leveling, which sets the angle grain cleaning up to 17% on the slopes, and also prevents the accumulation of grain while driving on the headland, which ensures even distribution and superior cleaning grain material.

Sieve adjustment FROM Seat

With changes in the properties of the culture, you can remotely adjust the sieve, not getting up from the chair. Open the screen while cleaning heavy crops to increase air flow. Reduce cell sieve light crops at harvest to prevent losses and to improve cleaning efficiency.

CR stores settings for different cultures

To minimize downtime, you need to change the settings when switching between crops or when you change the culture, combines CR system is used automatically adjust crops Automatic Crop Setting (ACS). This system allows you to save up to fifty sets of settings for different cultures. Operators can select the preset settings or programmed two parameters for each crop harvest, including the speed and position of the reel, the rotor speed and concave setting, cell sieve and cleaning fan speed, and then if necessary, choose your settings on the monitor IntelliView ™

The large capacity grain tank

Ultra-large grain tank for ultra high performance

Grain tank volume combine CR was increased in view of its high performance. Length of discharge screw was also increased to match the performance of a new generation of CR combines modern and reapers. New Holland has used all opportunities to increase production and CR Series combines your productivity.

Grain tank with high performance

11,500 liter grain tank can hold CR9080 combine is 9.5% more grain. It is possible to increase the time between unloading and reduce the cost of transporting grain. In addition, operators can devote more time to what they do best - the harvest. Grain tank cover as standard equipped with an electronic control folding and activated from the cockpit. Other benefits include reduced hopper grain loss when working on steep slopes and protection of grain left in the night. Inclined auger that distributes grain silo allowed to get rid of air pockets and local accumulations of grain in the bin.

Flexible solutions to meet your requirements

Combines CR Series can be equipped with the full range of tools, variable processing residue of different types of crops and methods of cultivation. To select the grinding residue or stacking rows, simply change the position of the special ergonomic lever. Tools are required. Replacement components are required. It's simple and fast. These different products and New Holland.

SYSTEM OPTI-SPREAD ™: BROAD spreading

If the processor is installed CR9080 biggest reaper (measuring 10.67 m) VariFeed ™, is absolutely necessary to use a special powerful system of spreading straw. The optional straw straw for Opti-Spread ™ easily satisfy any requirements for spreading width. This system is ideal when there is no or minimal number of operations to prepare the ground with the use of direct methods of treatment. System Management Opti-Spread ™ from cab. Two powerful splash drive regulated to operate in windy conditions or on a slope.

The ideal form of bales

Twin Rotor ™ technology provides an ideal linear flow of the grain material and eliminates the need for a sudden change in speed and direction. This allows you to retain the structure of the straw with a minimal amount of damage, even at maximum performance. This straw is perfect for pressing into bales. Feed straw beater sent to forced discharge conveyor. Double disc chaff can scatter chaff or lay it on the ground under the straw, compressed into bales.

Fine grinding. BROAD spreading

Straw New HollaNd

To be fully compliant with the performance combines New Holland CR company has developed a number of proprietary chaff. Select a configuration with four or six shredders and wind vanes mounted at the outer edges of the rotor for high performance spreading. High-speed (3500 r / min) chaff-cutter provides fine grinding and wide spreading of even the heaviest crops.

YOUR FIELD OFFICE

Panoramic view 360sdgR

Wide window with a convex glass in a comfortable cabin combiner provides an excellent overview of the entire header and unloading auger. The optional power mirrors allow you to see in all directions and adjustable from the cab. The new monitor IntelliView ™ IV allows you to connect up to three cameras review. They will be your eyes on the back of the head while unloading, reversing, check the level of grain in the bin.

BIGGEST AND QUIET CABIN

Combines a series of CR can be your home away from home at the time of harvest. Combiner comfortable cabin has a volume 3.12 m3, which is much higher than its nearest competitor. Peace and quiet in the cabin was achieved by reducing the noise level to 74 dB (A).

Are you comfortable in a chair

Seat, and a full-size instructor seat provides a comfortable fit for long-term operation. Optionally equipped with seat fabric or luxurious leather upholstery. Seat adjusts with fully adjustable for a comfortable fit operator of all.

BRIGHT LIGHTS FOR DARK NIGHTS

CR harvester turns night into day by the full set of working lights headlights as standard. At the end of a long day, you can safely leave the processor is in the light of a lantern, illuminating the stairs for 30 seconds after the ignition is turned off.

Cool even on the hottest days

Specially designed cooling compartment and optional refrigerator can have on hand a refreshing drink on hot work days. Air-conditioning is standard. By request you can set an automatic temperature control, which automatically adjusts fan speed to maintain the desired temperature to within one degree Celsius. Combine a series of CR will definitely become the coolest place in the heat.

MAXIMUM PERFORMANCE without hassle

Smart intuitive automation system saves time and increases productivity cleaning. Multifunction lever becomes indispensable during cleaning. You can adjust all the main parameters of the machine and the reaper, including the height of header, the position of the reel, the inclusion of discharge. In the right panel, ergonomically placed logically grouped rarely used functions. State machine functions, you can quickly check on the color monitor IntelliView ™ IV.

CLEANING FOR A WIDE SCREEN

Extra wide (31 cm) monitor IntelliView ™ IV is standard and mounted on the armrest. The operator can adjust the monitor to the desired position on the arc of the review. This intuitive color touch-screen monitors and displays all functions and parameters of the combine, which can be changed by simply touching the screen.

INTEGRATED SYSTEM FOR DETERMINING YIELD AND MOISTURE

The formulation of the CR series combines the functions laid precision agriculture. Information yield continuously updated and displayed on the monitor IntelliView ™ IV. This data can be stored, downloaded and analyzed in the software for precision farming to create accurate maps of yield. Cards can be used for accurate fertilizer to increase crop yields and reduce the cost of fertilizer.

DETERMINATION OF MOISTURE IN REAL TIME

The humidity sensor measures the company New Holland grain moisture content in real time. Samples were taken every 30 seconds, and the data is sent to the monitor IntelliView ™ IV. The operator is kept informed about the current state and may accordingly change the machine parameters.

CREATING yield maps

The patented high-precision sensor yields, developed by New Holland, is widely recognized as the best in class. Sensor design eliminates mechanical wear effects of grain. The sensor determines the yield extremely accurate regardless of the type, grade and moisture content in the grain. Moreover, the calibration is performed only once per season, and the system automatically adapts to the changing conditions and the type of culture.

360 °: CR

New CR series combines were created in response to reduce downtime for repair site. We all know how precious time in the field during the short period of harvesting. To all points of service has easy access, and significantly increased service intervals allow harvesters to spend more time in the natural environment - in the field!

• Standard and optional rotating brush hoods every two minutes a stream of compressed air at high pressure to clean the rotating dust shield. This is especially useful when harvesting corn.

• Easy access to the land to all the oil filter and drain points, as well as a central lubrication system increases the efficiency of maintenance.

• Self-supporting, fully operable covers provide easy access to all drives and service points.

• Plastic covers the rotor can be removed without tools, making it easier for seasonal inspections.

• Easy access to the air filter with a platform engine.

• The levels of engine oil and hydraulic oils can be easily checked without opening the panel.

Detection sensor that is part of a unique system of enhanced protection from stones (ASP), mounted under a closed bottom drum solomopodemnika. In the case of stone swinging door across the width is automatically opened by pushing a stone. This system requires minimal operator intervention and moves the net flow of grain material from the feeder to the rotor. This improves the quality of grain and straw, and productivity, not to mention the automatic protection of internal components supply system, which prolongs battery life.

Detection sensor that is part of a unique system of enhanced protection from stones (ASP), mounted under a closed bottom drum solomopodemnika. In the case of stone swinging door across the width is automatically opened by pushing a stone. This system requires minimal operator intervention and moves the net flow of grain material from the feeder to the rotor. This improves the quality of grain and straw, and productivity, not to mention the automatic protection of internal components supply system, which prolongs battery life. Hydraulics reverse instantly eliminates clogging header. Entire header and elevator can be dramatically shifted back and forth in order to effectively eliminate clogging machines to reduce downtime.

Hydraulics reverse instantly eliminates clogging header. Entire header and elevator can be dramatically shifted back and forth in order to effectively eliminate clogging machines to reduce downtime.

Combines CR Series can be equipped with the full range of tools, variable processing residue of different types of crops and methods of cultivation. To select the grinding residue or stacking rows, simply change the position of the special ergonomic lever. Tools are required. Replacement components are required. It's simple and fast. These different products and New Holland.

Combines CR Series can be equipped with the full range of tools, variable processing residue of different types of crops and methods of cultivation. To select the grinding residue or stacking rows, simply change the position of the special ergonomic lever. Tools are required. Replacement components are required. It's simple and fast. These different products and New Holland. Wide window with a convex glass in a comfortable cabin combiner provides an excellent overview of the entire header and unloading auger. The optional power mirrors allow you to see in all directions and adjustable from the cab. The new monitor IntelliView ™ IV allows you to connect up to three cameras review. They will be your eyes on the back of the head while unloading, reversing, check the level of grain in the bin.

Wide window with a convex glass in a comfortable cabin combiner provides an excellent overview of the entire header and unloading auger. The optional power mirrors allow you to see in all directions and adjustable from the cab. The new monitor IntelliView ™ IV allows you to connect up to three cameras review. They will be your eyes on the back of the head while unloading, reversing, check the level of grain in the bin. CR harvester turns night into day by the full set of working lights headlights as standard. At the end of a long day, you can safely leave the processor is in the light of a lantern, illuminating the stairs for 30 seconds after the ignition is turned off.

CR harvester turns night into day by the full set of working lights headlights as standard. At the end of a long day, you can safely leave the processor is in the light of a lantern, illuminating the stairs for 30 seconds after the ignition is turned off. The humidity sensor measures the company New Holland grain moisture content in real time. Samples were taken every 30 seconds, and the data is sent to the monitor IntelliView ™ IV. The operator is kept informed about the current state and may accordingly change the machine parameters.

The humidity sensor measures the company New Holland grain moisture content in real time. Samples were taken every 30 seconds, and the data is sent to the monitor IntelliView ™ IV. The operator is kept informed about the current state and may accordingly change the machine parameters. The patented high-precision sensor yields, developed by New Holland, is widely recognized as the best in class. Sensor design eliminates mechanical wear effects of grain. The sensor determines the yield extremely accurate regardless of the type, grade and moisture content in the grain. Moreover, the calibration is performed only once per season, and the system automatically adapts to the changing conditions and the type of culture.

The patented high-precision sensor yields, developed by New Holland, is widely recognized as the best in class. Sensor design eliminates mechanical wear effects of grain. The sensor determines the yield extremely accurate regardless of the type, grade and moisture content in the grain. Moreover, the calibration is performed only once per season, and the system automatically adapts to the changing conditions and the type of culture.